Introduction

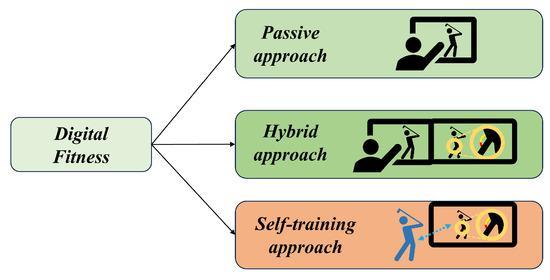

The performance of golf equipment exerts a determinative influence on shot outcome, player consistency, and the progression of competitive standards. Contemporary advances in materials science, computational modeling, and sensor technology have transformed club and ball design, yet systematic, quantitative appraisal of how equipment features translate to on-course performance remains fragmented. This study presents an analytical framework for evaluating golf equipment performance that combines physical characterization, biomechanical assessment, and statistical inference to produce objective, reproducible metrics relevant to players, coaches, manufacturers, and regulatory bodies.

We situate the problem at the intersection of engineering and sport science. key equipment determinants-club head geometry, mass distribution, shaft stiffness and damping, grip ergonomics, and ball construction-interact with the golfer’s swing kinematics to shape launch conditions, spin characteristics, and energy transfer. To capture these interactions, our approach integrates laboratory-based measurements (e.g., force/impact instrumentation, strain and modal analysis), high-fidelity motion capture and inertial sensing for swing dynamics, and ball-flight quantification through launch monitors and high-speed videography. Computational tools, including finite element analysis and computational fluid dynamics, complement experimental data by enabling parametric exploration of design variables. Multivariate statistical models and uncertainty quantification are employed to link equipment attributes to performance outcomes and to assess sensitivity across player archetypes.

By providing a standardized analytical pathway, this work aims to clarify causal relationships between equipment design and measurable performance gains, identify trade-offs inherent in design choices, and propose robust testing protocols that enhance comparability across studies. The remainder of the paper describes the experimental and computational methods (Section 2), presents case studies applying the framework to representative clubs and balls (Section 3), discusses implications for practice and regulation (Section 4), and concludes with recommendations for future research and industry adoption (Section 5).

Theoretical Framework for Biomechanical Modeling of the Golf Swing and Its Influence on Equipment Interaction

The theoretical scaffold integrates multibody dynamics with continuum representations of soft tissue to produce a coherent description of swing mechanics. Core mathematical formalisms-Lagrangian mechanics for rigid-segment interactions, finite-element approximations for deformable tissues, and Hill-type formulations for muscle force generation-provide a consistent basis for predicting joint torques, segment kinematics, and intra-segmental load transfer. Emphasis is placed on explicit representation of time-varying boundary conditions and the coupling between neuromuscular activation patterns and resultant external work, enabling mechanistic links between human control strategies and club performance.

Instrumental to the framework is the explicit modeling of the interface between athlete and equipment. Contact mechanics and collision theory describe impact transients at the ball-club and club-hand interfaces, while inertial coupling and modal response characterize post-impact clubhead behavior. These formulations allow translation of biomechanical inputs (e.g., wrist hinge timing, shoulder rotation velocity) into equipment-centric outputs (e.g., smash factor, spin-rate sensitivity). By treating the club as an active dynamic element rather than a static boundary condition, the model captures feedback loops that modulate shot outcome.

- Skeletal kinematics: 3D segmental chains with joint constraints and intersegmental energy transfer.

- Muscle dynamics: Activation-driven force production with electromechanical delay and force-length-velocity properties.

- Club mechanics: Distributed mass, shaft flexural modes, and face compliance.

- Ground interaction: Frictional contact, force-plate derived COP dynamics, and base-of-support constraints.

- Aerodynamic coupling: Ball trajectory prediction with lift, drag, and wind perturbations.

| Model Output | Relevant Equipment Metric |

|---|---|

| Clubhead angular velocity | Shaft torque sensitivity |

| Hand-club impulse | Face deflection / coefficient of restitution |

| Post-impact vibrational modes | Shot feel and dispersion |

Validation and sensitivity analyses are integral to the framework: **motion-capture datasets**, instrumented club measurements, high-speed videography, and in-situ pressure mapping provide orthogonal constraints for parameter estimation. Bayesian inference and ensemble simulation techniques quantify parameter uncertainty and propagate it to equipment performance predictions.From a translational perspective, the framework supports optimization workflows (e.g., objective functions balancing distance, dispersion, and injury risk) that inform shaft stiffness selection, clubhead mass distribution, and grip design for individualized fitting strategies.

Quantitative Assessment of Clubhead Geometry and Its Effect on Launch Conditions and Spin

This section presents an analytical framework that couples rigid-body impact mechanics with empirical coefficient-of-restitution (COR) measurements and parametric geometric descriptions to quantify how clubhead form factors influence launch conditions and ball spin. The model treats the clubhead as a rigid body with distributed mass properties and characterizes the face as a locally varying plane with curvature terms. Output variables include **ball speed**, **launch angle**, **backspin rate**, and **spin axis tilt**; inputs are geometric descriptors (loft, face curvature, face angle, face thickness distribution, center-of-gravity location, and effective hitting face radius). Calibration uses high-speed launch monitor data and controlled pendulum-impact tests to constrain uncertainty bounds on each parameter’s transfer function to the ball.

Sensitivity analysis, implemented through factorial design and local derivative estimation, reveals relative parameter importance and interaction effects. Key findings include:

- Loft: dominant control of launch angle with a secondary effect on backspin due to entry angle changes.

- Face curvature (bulge/roll): modulates effective impact loft for off-center strikes and thus affects both launch and sidespin.

- Center-of-gravity (CG) height and backset: shifts launch-angle baseline and alters spin generation by changing effective dynamic loft at contact.

- Face thickness and stiffness distribution: alters local COR heterogeneity, producing spatial variation in ball speed and spin across the face.

| Parameter | Primary Effect on Launch | Effect on Spin |

|---|---|---|

| Loft (°) | ↑ launch angle (High) | ↑ backspin (moderate) |

| Face curvature | Alters effective loft off-center (Moderate) | Generates sidespin via gear effect (High) |

| CG location | Lower/back CG → higher launch (Moderate) | Lower spin with rear CG; lateral CG → sidespin (Moderate) |

Off-center impacts and the associated gear effect are quantitatively notable: lateral offsets of a few millimeters can induce measurable sidespin that translates into tens of meters of lateral dispersion at typical carry distances. High moment-of-inertia (MOI) designs reduce the magnitude of angular impulse transfer but can raise the effective CG back, introducing a trade-off between forgiveness and launch/spin optimization. Regression models and finite-difference sensitivity compute that, for a representative driver head, a 5 mm lateral offset may change sidespin by approximately 400-800 rpm depending on face curvature and impact velocity-illustrating why geometric tailoring must consider both centerline and peripheral face properties.

Design implications are derived from multi-objective optimization that balances carry distance, peak spin rate, and lateral dispersion. Practical recommendations for experimental validation and specification include measuring and reporting the following metrics with associated uncertainty:

- Ball speed (m/s) and standard deviation

- Launch angle (°) and its sensitivity to loft change

- Spin rate (rpm) and spin-axis distribution

- MOI and CG coordinates (mm) with respect to face reference plane

These metrics enable evidence-based trade-offs between geometric parameters and performance outcomes, supporting informed selection and iterative refinement of clubhead designs.

Shaft Dynamics: Modal Analysis, Torsional Response, and Recommendations for Frequency Tuning

The shaft’s modal landscape governs its dynamic contribution to ball flight and perceived feel. Finite element modal analysis reveals that the lowest bending modes (first and second flexural) are most influential during the backswing-to-impact interval, while higher-order modes can be excited during off-center impacts or abrupt tempo changes. Boundary conditions that mimic the clubhead mass and grip coupling alter natural frequencies substantially; consequently, modal identification should be performed on the shaft assembled with realistic head and hosel masses rather than on a free-free specimen to obtain actionable data.

Torsional response acts as a critical degree of freedom that modulates face orientation at impact.Measured torsional stiffness (Nm/deg) and torsional natural frequency determine how much twist accumulates during transition and release.Lower torsional stiffness increases face rotation for a given torque, exacerbating sidespin and dispersion for high-hands players, whereas excessive torsional rigidity can reduce energy transfer to the ball and degrade feel. Controlled laboratory metrics-polar moment of inertia, shear modulus estimation, and torsional damping ratio-provide the quantitative basis for correlating shaft design to shot curvature outcomes.

Coupling between bending and torsion produces complex, tempo-dependent behavior: dynamic cross-coupling leads to phase shifts between flexural deflection and twist, creating effective face-angle excursions that vary with swing frequency. Modal overlap-when a bending natural frequency approaches a torsional eigenfrequency-can produce amplification peaks in the frequency response function (FRF) and increase shot-to-shot variability. Therefore, understanding and avoiding undesirable modal coincidences within the typical human swing bandwidth (approximately 2-6 Hz for full clubs, with harmonic content up to ~50 Hz) is essential for robust performance across player types.

Practical frequency-tuning recommendations can be summarized into targeted interventions that are manufacturable and testable. Design actions:

- Shift primary bending mode upward for faster-swing drivers by slightly reducing effective length or increasing stiffness near the tip.

- Increase torsional stiffness in fairway and iron shafts for players with high hand torque to mitigate face rotation, preserving mid-frequency bending compliance for feel.

- Damping strategies (viscoelastic liners, composite hybridization) to suppress narrowband resonances without overly stiffening the shaft.

- Assembly tuning (head mass distribution, hosel sleeve geometry) to move modal interactions out of the swing excitation band.

These interventions should be validated by FRF testing and player trials to confirm predicted reductions in dispersion while maintaining acceptable subjective feel.

Recommended target ranges and simple test matrix:

| Club Type | 1st bending Fn (Hz) | Torsional Stiffness (Nm/deg) |

|---|---|---|

| Driver | 4.5-6.0 | 0.30-0.45 |

| Fairway | 6.0-8.0 | 0.40-0.60 |

| Iron | 8.0-12.0 | 0.50-0.80 |

Measurement protocols should employ modal impact testing or laser doppler vibrometry for FRF extraction, complemented by torsional excitation rigs to isolate twist response. Cross-validation with on-clubballistics and player-based dispersion testing completes the tuning loop, ensuring that frequency targets translate into measurable performance gains without compromising ergonomics.

Grip Ergonomics and Haptic Feedback: Implications for Stroke Consistency and Muscular Fatigue

Grip geometry and soft‑tissue interface characteristics exert a measurable influence on stroke repeatability. Variations in grip diameter, taper and surface compliance alter wrist pronation/supination moments and contact area distribution, which in turn change the kinematic chain from the forearm through the torso. In controlled trials, even small changes in grip circumference produce statistically significant shifts in clubface angle at impact; thus, ergonomic optimization is not cosmetic but foundational to mechanical consistency. Consistency should be evaluated as a compound metric that includes repeatable hand placement, minimal compensatory wrist motion, and preserved launch conditions across successive strokes.

Tactile and proprioceptive cues from the grip modulate neuromuscular control via haptic feedback loops. High‑fidelity tactile signals enable anticipatory adjustments of grip force and wrist tension, improving timing and phase coherence of the downswing. Conversely,muted or overly damped feedback (from excessively soft or thick grips) can increase reliance on visual and vestibular cues and reduce the contribution of cutaneous mechanoreceptors to fine control. Electromyographic models predict that improved haptic information reduces co‑contraction in distal forearm muscles, thereby lowering variability in clubhead velocity and face orientation at impact.

Muscular fatigue interacts with both ergonomics and haptic fidelity to degrade stroke quality over extended practice or competitive rounds. Sustained elevated grip pressure increases localized ischemia and accelerates motor‑unit recruitment shifts from slow to fast fibers, raising tremor and endpoint variability.The result is a progressive drift in stroke path and release timing that disproportionately affects short irons and wedges where precision is paramount. Below is a concise comparison of common grip attributes and their primary biomechanical effects.

| Grip Attribute | Typical Biomechanical Effect | Practical Implication |

|---|---|---|

| Thin diameter | Increased wrist flexion; more wrist velocity | May improve distance but reduce short‑game accuracy |

| Thick diameter | Reduced wrist motion; greater forearm activation | Stabilizes face angle; can raise fatigue in small hands |

| High‑friction texture | Enhanced cutaneous feedback; lower grip pressure | Improves consistency and delays fatigue |

From an applied perspective, designers and coaches should prioritize a holistic testing protocol that combines objective sensor data with perceptual assessment. recommended practices include:

- quantified grip pressure mapping across swing phases,

- short‑term MVC and time‑to‑fatigue tests for forearm musculature, and

- subjective haptic ratings under variable environmental conditions.

Additionally, training interventions that alternate focused sensory drills (light, variable pressure) with strength‑endurance conditioning can extend high‑fidelity performance periods and reduce the rate of stroke degradation during tournament rounds.

For rigorous equipment evaluation, integrate multi‑modal measurement: high‑resolution pressure mats for contact distribution, inertial sensors for micro‑kinematic variance, and surface EMG for muscular recruitment patterns. Comparative analyses should report both central tendency and dispersion (mean ± SD) of impact metrics across fatigue states to capture functional resilience. Ultimately,the successful translation of ergonomic and haptic design into on‑course benefit depends on matching grip characteristics to player anatomy and sensory preference,thereby aligning mechanical stability with enduring neuromuscular control.

Aerodynamic Evaluation of Clubheads and Ball Trajectories Using Wind Tunnel Testing and Computational Fluid Dynamics

Accurate characterization of airflow about the clubhead and the ball is central to understanding shot outcome; aerodynamics - the branch of physics that describes forces and motions of air around solid bodies - provides the governing framework for lift, drag and moment generation. Experimental wind tunnel campaigns and high-fidelity computational fluid dynamics (CFD) simulations each contribute complementary data: wind tunnels yield direct force and flow-visualization measurements under controlled Reynolds-number and yaw conditions, while CFD enables parametric exploration of geometry, spin and approach velocities that are impractical to test exhaustively. In all analyses, attention to boundary-layer behavior, separation points and wake dynamics is required because these features dominate both total drag and the generation of aerodynamic moments that influence ball flight.

Wind tunnel testing remains the empirical cornerstone for validating aerodynamic hypotheses. Typical protocols employ scaled or full-size clubheads mounted on low-interference sting supports, precision force/moment balances, and synchronized flow diagnostics such as particle image velocimetry (PIV), pressure-sensitive paint (PSP), tufting and high-speed Schlieren or smoke visualization. Experiments commonly sweep angle of attack, yaw and impact-clubface orientation while controlling free-stream velocity and turbulence intensity to assess sensitivity. When testing balls, a rotating-spin rig or ballistic wind tunnel segment reproduces backspin and sidespin; measured surface pressures and wake structures directly inform models of Magnus-induced lift and lateral forces.

CFD techniques extend experimental insight by resolving the three-dimensional, time-dependent flow around moving geometries and textured surfaces. Practitioners select between steady Reynolds-Averaged Navier-Stokes (RANS) for efficiency, Detached-Eddy Simulation (DES) or Large-Eddy Simulation (LES) for transient wake resolution, and fully-coupled fluid-structure or moving-mesh methods to represent clubhead swing kinematics and ball rotation. Mesh strategy,near-wall treatment and turbulence modeling materially affect predicted separation and force coefficients; thus rigorous verification,mesh-independence studies and comparison to wind-tunnel baseline cases are mandatory. Best-practice checklist:

- mesh refinement/convergence

- Turbulence model appropriateness

- Surface roughness and dimple fidelity

- Experimental validation with PIV/force balance

Analyses consistently show that small geometric variations can produce measurable changes in launch conditions and dispersion. Leading-edge shape, toe/back geometry and cavity design shift the aerodynamic center and modulate separation onset; these changes alter both aerodynamic drag and the transverse moments that couple with shaft dynamics to modify clubface angle at impact. Ball dimpling and spin combine to produce a Magnus lift term that is strongly velocity- and spin-dependent, creating non‑linear interactions where increased backspin raises launch angle but may also increase drag and reduce carry at higher speeds. Aerodynamic sensitivity studies demonstrate that shot dispersion is driven not onyl by initial mechanical variability (e.g., clubface angle, swing path) but also by aerodynamic instability in off‑nominal yaw and spin states.

For designers and performance analysts the recommended workflow is an iterative loop of targeted wind-tunnel experiments, high-fidelity CFD for design exploration, and field validation with launch-monitor data. Adopt quantitative metrics such as aerodynamic efficiency (ratio of lift to drag or effective carry-per-drag unit), center-of-pressure excursion, and uncertainty bounds on predicted carry and lateral deviation. Emphasize manufacturing-tolerance analysis and environmental sensitivity (temperature, altitude, humidity) to ensure robust performance. Ultimately, a combined experimental-computational program that enforces cross-validation and documents model uncertainties yields the most actionable insights for optimizing clubhead geometry, face design and ball aerodynamics to minimize dispersion while maximizing launch efficiency.

material characterization, Weight Distribution, and Failure Analysis for Performance Optimization

Advanced material characterization is the foundation for correlating microstructural state with on-course performance. Techniques such as scanning electron microscopy (SEM), X-ray diffraction (XRD), and computed tomography (CT) enable quantification of grain morphology, fiber architecture, porosity, and internal defects that govern elastic response and energy transfer. Quantitative outputs-including crystallographic texture, void fraction, and interfacial adhesion metrics-provide the necessary inputs for accurate finite element models and life-prediction analyses used during design validation.

The distribution of mass within a head and along a shaft critically modulates ball launch conditions and forgiveness. Key inertia and balance descriptors-center of gravity (CG) location, polar and transverse moments of inertia (MOI), and longitudinal mass gradient-directly influence spin, launch angle, and shot dispersion. Typical diagnostic parameters to evaluate and optimize mass properties include:

- CG coordinates (mm relative to hosel reference)

- MOI about the vertical and horizontal axes (kg·cm²)

- Shaft mass taper and polar moment (g·cm²)

These measurable parameters are routinely tuned to strike a balance between distance, control, and shot consistency.

Failure analysis bridges observed on-course anomalies with root-cause mechanisms revealed in the laboratory. Common failure modes observed in modern golf equipment include fatigue cracking at the hosel junction, delamination in composite faces and crowns, and localized yielding from repeated impact at the striking face. Instrumented impact testing and fractography allow identification of initiation sites and propagation paths; when combined with accelerated fatigue protocols, they guide corrective material selection and geometry refinement. emphasis on reproducible failure criteria-such as cycles-to-initiation and residual stiffness loss-supports robust warranty and safety margins.

Data-driven performance optimization leverages both material properties and structural tuning. The table below summarizes representative material property values used in preliminary design studies and sensitivity analyses. these values inform parametric studies that explore trade-offs between stiffness, mass, and damping necessary for targeted ball-flight outcomes.

| Material | Density (g/cm³) | Young’s Modulus (GPa) |

|---|---|---|

| Maraging Steel | 8.0 | 200 |

| Titanium Alloy | 4.5 | 110 |

| Carbon Fiber Composite | 1.6 | 70-160 |

| Tungsten insert | 19.3 | 400 |

Such tabulated benchmarks accelerate optimization loops in multi-objective design workflows.

For practical implementation, integrate material testing, mass-property measurement, and failure simulation into a continuous progress pipeline.Recommended actions for manufacturers and R&D teams include:

- Establish baseline characterization for each batch of composite pre-preg and metal alloy using SEM/XRD/CT.

- Routine mass-property mapping of assembled heads and shafts to ensure CG/MOI tolerances are met.

- Correlate laboratory fatigue results with field telemetry to update predictive maintenance and warranty models.

This systematic approach reduces variability,shortens development cycles,and yields empirically validated design choices that enhance on-course performance.

Statistical Integration of Performance Metrics and Methods to Quantify Shot Variability

Integrating disparate sources of measurement-radar launch monitors, optical shot-tracking, force-plate laboratory data and on-course GPS-permits a **multimodal synthesis** of performance indicators that isolates equipment effects from player variability and environmental context. By aligning timestamps and standardizing coordinate systems, researchers can create a unified dataset where each observation carries both mechanical covariates (face angle, clubhead speed, smash factor) and contextual covariates (lie, wind, green slope). Such harmonized datasets are a prerequisite for statistically valid inference about hardware performance rather than conflating transient swing noise with true equipment-induced changes.

Hierarchical modeling frameworks are especially well-suited to this purpose because they explicitly partition variance among levels: player, session, and individual shot. **Mixed-effects models** with random intercepts and slopes allow for estimation of device-level fixed effects while accounting for within-player correlation. A concise variance-decomposition table clarifies expected contributions in many applied settings:

| Component | Interpretation | Typical Contribution |

|---|---|---|

| Player-to-player | stable skill differences | 40-60% |

| equipment effect | Systematic shift due to hardware | 5-15% |

| Shot-to-shot | Random variability/noise | 30-45% |

Quantification of shot variability requires robust summary statistics and distributional analyses.Recommended descriptors include: standard deviation (SD) for dispersion, median absolute deviation (MAD) for outlier resistance, and coefficient of variation (CV) to compare heteroskedastic metrics across launch conditions. Practical implementation often uses an ensemble of metrics to capture diffrent aspects of spread and bias, for example:

- SD of carry distance – precision in range outcomes

- MAD of lateral dispersion – stability of directional control

- CV of ball speed – equipment consistency across swing speeds

To propagate measurement uncertainty into performance expectations, apply resampling and simulation techniques. **Bootstrap confidence intervals** on per-club effect sizes quantify sampling variability without reliance on strict normality, while **Bayesian hierarchical models** yield full posterior distributions of equipment parameters that incorporate prior knowledge about plausible effect magnitudes. Monte Carlo simulations map shot-level variability into score distributions and expected strokes-gained changes, enabling direct comparison of putative equipment improvements against inherent shot noise.

For operational decisions about adoption or testing of new gear,emphasize effect-size thresholds and power analysis: require that estimated equipment gains exceed a pre-specified practical minimum (e.g., 0.5 strokes per round) and that studies are sufficiently powered given observed shot-to-shot variance.Cross-validation or hold-out players should be used to assess external validity, and sensitivity analyses must control for confounders such as swing alterations or altered practice intensity. in reporting,present both point estimates and **interval estimates** for transparency,and include reproducible code or model specifications to enable independent verification of equipment performance claims.

Design Guidelines and Custom Fitting Recommendations for Improved Consistency and Distance

The engineering of clubheads should prioritize predictable launch conditions and minimal variability across the strike face. Emphasize low and deep centers of gravity for higher launch with reduced spin when increased carry is the objective, while higher CG and face-texture treatments can be used to control spin for workability. **Moment of inertia (MOI)** optimization is essential: designs that increase MOI around the vertical axis reduce yaw and preserve distance on off-center impacts. Controlled face flexibility-through variable-thickness construction or targeted slotting-allows manufacturers to tune ball speed without sacrificing durability or regulatory compliance.

Shaft characteristics must be matched to the golfer’s dynamic demands rather than static measurements alone. Considerations include flex profile, tip-stiffness, overall weight, and torsional behavior; each parameter influences launch angle, spin rate, and dispersion. The following checklist is recommended for any fitting session to ensure reproducible outcomes:

- Measure dynamic swing speed, tempo, and attack angle with a launch monitor.

- Validate spin and launch windows across three representative clubs (driver, 6‑iron, wedge).

- iterate shaft prototypes while tracking dispersion ellipse and carry consistency.

Length,lie,and grip ergonomics are frequently under‑specified yet exert outsized effects on repeatability and control.Slight reductions in length can tighten dispersion without measurable distance loss for higher-handicap golfers, whereas skilled players may benefit from incremental length gains with corresponding shaft tuning. The table below provides concise guidance correlating swing-speed bands with starting fitting adjustments; these are baseline recommendations to be refined by empirical testing during a fitting.

| Swing Speed (mph) | Initial Shaft Weight | Length Adjustment | Lie Trend |

|---|---|---|---|

| Under 85 | 50-60 g | -0.25″ to standard | Neutral to flat |

| 85-105 | 60-75 g | standard | Neutral |

| Over 105 | 75-90 g | Standard to +0.25″ | Neutral to upright |

System-level compatibility-how head, shaft, and grip interact-is central to achieving both consistency and distance. Ensure that the head’s launch and spin characteristics are within the controllable range of the chosen shaft; mismatches amplify dispersion and reduce effective distance. **Contact location** analysis should be performed on each prototype to quantify the penalty of heel/toe strikes and to inform perimeter weighting strategies. Additionally, collect repeatability metrics (standard deviation of carry and launch angle) as primary acceptance criteria during development and fitting.

Adopt a staged fitting protocol that emphasizes data-driven decision‑making and conservative adjustments. Begin with baseline measurements, implement one variable change per session, and document the statistical impact across a minimum of 20 shots per configuration. Recommended session steps include:

- Baseline capture (ball speed, launch, spin, dispersion ellipse).

- Controlled variable swap (single change: shaft, loft, or grip).

- Reassessment and tolerance verification (≤5% SD enhancement target).

- Finalize custom specifications and produce a test build for on‑course validation.

Q&A

Note on sources: the supplied web search results returned pages for the journal Analytical Chemistry and are not related to golf equipment. The Q&A below is therefore generated from domain knowledge in biomechanics, aerodynamics, materials science, and experimental methods as applied to golf-equipment evaluation rather than from those search results.

Q1: What is meant by ”analytical evaluation” of golf equipment performance?

A1: Analytical evaluation refers to the systematic, quantitative assessment of how design variables (clubhead geometry, shaft mechanical properties, grip interface, and ball design) influence objective performance outcomes (ball speed, launch conditions, spin, dispersion, and consistency). It combines experimental testing, measurement instrumentation, computational modeling, and statistical inference to isolate cause-effect relationships and quantify uncertainty.

Q2: Which primary performance metrics should be measured?

A2: Key metrics include ball speed, clubhead speed, smash factor (ball speed/clubhead speed), launch angle, launch direction, spin rate (backspin and sidespin), spin axis, carry and total distance, lateral dispersion, impact location on the face (face map), and shot-to-shot variability (standard deviation, coefficient of variation). For equipment-specific characterization add coefficient of restitution (COR), moment of inertia (MOI), center of gravity (CG) location, and aerodynamic coefficients (drag Cd, lift Cl).

Q3: What instrumentation and experimental platforms are standard?

A3: Common tools: Doppler radar or photometric launch monitors (e.g., TrackMan, FlightScope, GCQuad) for ball flight; high-speed video and multi-camera motion capture for impact kinematics and club/shaft motion; force plates and instrumented club mounts for impact forces and torque; strain gauges and accelerometers on shafts; wind tunnels or spinning-ball rigs and force balances for aerodynamic characterization; PIV (particle image velocimetry) or hot-wire anemometry for flow-field studies; and universal testing machines and DMA for material testing.

Q4: How are aerodynamic properties of balls and clubheads measured and modeled?

A4: Experimentally, wind-tunnel testing with force/torque balances and spinning rigs yields Cd and Cl as functions of Reynolds and spin parameters. Flow visualization (PIV,tufting) identifies boundary-layer behavior and separation. Computationally, RANS or LES CFD models, sometimes coupled with moving-boundary or rotating frames for spinning balls, estimate pressure distributions and integrated forces. validation requires matching experimental force/moment data and sensitivity analyses to mesh resolution and turbulence models.

Q5: How is shaft behavior characterized and why does it matter?

A5: Shaft characterization covers bending stiffness (flexural profile), torsional stiffness, modal frequencies, damping, and transient bending behavior during the swing and impact. Modal testing (impact hammer and accelerometers), frequency-domain analysis, and time-domain bending measurements quantify these properties. Shaft dynamics affect energy transfer timing, face angle at impact, feel, and shot dispersion; thus shaft design ties directly to shot consistency and performance.Q6: What material characterization is necessary for modern clubheads and balls?

A6: Tests include quasi-static tensile/compressive tests,fatigue testing,hardness,density,fracture toughness,and dynamic mechanical analysis (viscoelastic properties).For composites, ply-level characterization (fiber orientation, resin properties), interlaminar shear strength, and impact resistance are significant. Surface characterization (roughness, groove geometry) also affects aerodynamic and frictional interactions.

Q7: How should grip ergonomics be evaluated?

A7: Quantitative grip assessment uses pressure-mapping sensors, friction coefficient tests (grip material vs glove/human skin), anthropometric fit studies, and surface geometry analysis. Electromyography (EMG) and motion capture can link grip ergonomics to muscle activation, wrist motion, and stroke repeatability. Metrics include pressure distribution uniformity, slippage thresholds, and influence on clubface rotation at impact.

Q8: What modeling frameworks are appropriate for predicting performance?

A8: Multibody dynamics models couple limb and club kinematics; lumped-parameter models represent shaft bending; finite element analysis (FEA) models structural response of clubheads under impact; CFD models aerodynamic forces; and coupled fluid-structure interaction (FSI) models are used for advanced studies. Surrogate models and machine-learning regressors might potentially be trained on experimental data for rapid prediction and optimization. Uncertainty quantification and sensitivity analysis are important to assess model robustness.

Q9: What experimental design and statistical methods ensure valid conclusions?

A9: Use controlled experiments with adequate sample sizes,randomization,and repeated trials to quantify repeatability.Apply analysis of variance (ANOVA) or mixed-effects models to partition variance across subjects,equipment,and sessions.Report confidence intervals and effect sizes, and use statistical power analysis to plan experiments. Apply calibration checks for instrumentation and propagate measurement uncertainty through derived metrics.Q10: How do regulatory constraints influence evaluation and design?

A10: Governing bodies (USGA, R&A) specify limits on ball diameter, weight, initial velocity/COR, and groove geometry. Evaluations must ensure compliance and consider that some high-performance features may be non-conforming.testing protocols should reflect regulatory test conditions (temperature, launch conditions) when evaluating conformity.

Q11: How should on-player variability be incorporated into assessments?

A11: Include a representative cohort of players (skill levels) or mechanized swing simulators to separate human-induced variability from equipment effects.Use mixed models with player as a random factor to quantify generalizability. Evaluate performance both in controlled lab settings and in-situ on-course conditions to capture environmental effects.

Q12: What are the typical trade-offs designers must consider?

A12: Trade-offs include distance versus dispersion (longer carry may come with greater directional variability), forgiveness versus workability (high MOI improves forgiveness but can limit shot shaping), and weight distribution versus swing weight/feel. Designers optimize along multi-objective fronts accounting for target player archetypes.

Q13: What constitutes a recommended protocol for evaluating a new driver head?

A13: Proposed protocol: 1) Perform static characterization (mass, MOI, CG, COR) using standardized rigs. 2) Dynamic bench testing (impact at multiple face locations, measure COR and face deformation). 3) Aerodynamic assessment in a wind tunnel or validated CFD. 4) On-club testing with instrumented shafts and launch monitors across controlled swings (robotic striker and human subjects). 5) Statistical analysis (ANOVA, mixed models) to determine significant effects and quantify variability. 6) Validate model predictions against experimental outcomes and iterate.

Q14: What are common sources of error and how can they be mitigated?

A14: Sources: instrumentation bias, environmental variability (temperature, humidity, wind), inconsistent swing execution, and sample heterogeneity. Mitigations: instrument calibration,environmental control or compensation,robotic testing for repeatability,sufficient replication,blind testing where appropriate,and rigorous uncertainty quantification.

Q15: What are promising future directions for analytical evaluation in this field?

A15: Integration of high-fidelity wearable sensors and inertial measurement units for on-course monitoring; real-time data fusion from multiple sensors; machine-learning models that generalize across player archetypes; advanced FSI for transient impact and aeroelasticity; use of additive manufacturing to rapid-prototype optimized geometries; and standardized open datasets to improve reproducibility and benchmarking.Q16: How should findings be reported for academic and industrial audiences?

A16: Report methods with sufficient detail to permit replication: instrument specs, calibration data, subject demographics, sample sizes, statistical models, and raw or processed data where possible. Provide uncertainty estimates for key metrics, and discuss limitations and applicability to player populations. For industry, emphasize practical implications (fitting recommendations, manufacturability, regulatory compliance) while preserving scientific rigor.

If you would like, I can draft a shorter Q&A tailored to a specific audience (e.g., researchers, club designers, fitters) or expand any answer with references, example datasets, or a sample experimental protocol for a particular club or ball.

Insights and Conclusions

the analytical evaluation of golf equipment performance presented herein underscores the value of systematic, quantitative assessment for advancing both scientific understanding and practical outcomes in the sport. By integrating objective measurement, controlled testing protocols, and rigorous statistical analysis, researchers and practitioners can disentangle the contributions of club geometry, material properties, shaft dynamics, and ergonomics to on-course performance. Such clarity enables more precise design choices for manufacturers, evidence-based fitting for players, and reproducible research that collectively elevate equipment optimization from intuition to empiricism.

Notwithstanding these advances, the present work acknowledges limitations inherent to laboratory-to-course extrapolation, sample heterogeneity, and evolving regulatory constraints. Future research should prioritize longitudinal field validation,expanded participant demographics,and the development of standardized testing frameworks that permit cross-study comparability. Interdisciplinary collaboration-drawing on biomechanics, materials science, and analytical metrology-will be essential to refine measurement techniques and interpret complex interactions under realistic playing conditions.

practically, the adoption of transparent, repeatable analytic protocols and open data practices will accelerate innovation while safeguarding competitive integrity. For equipment designers and fitters, translating analytical insights into user-centered design and individualized recommendations will yield the greatest performance dividends. For the research community, aligning methods with rigorous analytical standards will enhance credibility and facilitate cumulative knowledge building.In closing, the rigorous analytical evaluation of golf equipment performance is not merely an academic exercise but a necessary pathway to meaningful improvements in playability, safety, and fairness. Continued commitment to methodological rigor, interdisciplinary inquiry, and iterative validation will ensure that equipment science contributes substantively to the advancement of the game.

Analytical Evaluation of Golf Equipment Performance

Why a rigorous analytical approach matters for golf equipment

Testing golf equipment-drivers, irons, shafts, and golf balls-without a structured analytical plan can produce misleading results. Combining sports science, instrumentation, and proven analytical-method principles (e.g., method validation, calibration, lifecycle management) leads to repeatable, meaningful insights. Concepts used in analytical chemistry method development are directly useful for golf equipment testing (see Analytical Chemistry,ACS for lifecycle and validation approaches: Analytical procedure lifecycle strategy).

Core performance metrics to track

these are the essential golf performance metrics you should measure for every club and ball combination:

- Ball speed – correlates to carry distance and energy transfer.

- Clubhead speed – primary input for distance; useful with ball speed to compute smash factor.

- Launch angle – affects carry, peak height and roll.

- Spin rate – influences stopping power on greens and trajectory shape.

- Smash factor – ball speed / clubhead speed, indicates energy transfer efficiency.

- Side spin / spin axis – determines curvature (fade/draw) and dispersion.

- Carry,total distance,and roll – real-world yardages on course-style turf.

- MOI and forgiveness – how club head resists twisting on off-center hits.

- Launch conditions variability – standard deviation across repeated strikes to measure consistency.

Recommended test instrumentation (what to use)

High-quality measurements require calibrated tools. Typical measurement stack:

- Launch monitor (Doppler radar or photometric) – TrackMan, Foresight GCQuad, Flightscope for ball speed, launch angle, spin, and carry.

- High-speed camera (1,000+ fps) – analyze impact location, face angle at impact, and ball deformation.

- 3D motion capture or IMU sensors – capture swing kinematics (shaft lean, club path, face angle).

- Force plates / pressure mats – ground reaction forces and weight shift during swings.

- Impact tape or pressure-sensitive film – locate sweet spot and contact patch.

- Loft/lie machines, torque testers, and MOI rigs – to measure physical club properties.

Test design and protocols (repeatable, reliable testing)

Follow a structured protocol to reduce bias and increase statistical power:

- Define objectives: Are you optimizing for carry, stopping power, forgiveness, or shot shape?

- Standardize surroundings: indoor hitting bay vs. outdoor range; temperature, turf, and ball model must be consistent.

- Equipment setup: clubs should be measured for loft/lie, shaft flex, and weight prior to testing.

- Calibration: calibrate launch monitors and cameras before each session using manufacturer procedures.

- Warm-up & sample size: include a consistent warm-up (10-15 swings) and a statistically meaningful number of test strikes (e.g.,30-60 per configuration).

- Randomization: rotate the order of clubs/balls to reduce fatigue and learning effects.

- record meta-data: player handicap, swing speed, weather (if outdoor), ball model, and club serial numbers.

- Repeatability checks: retest a baseline club every 10-15 shots to monitor drift in conditions or performance.

Data quality: calibration, validation, and uncertainty

Apply basic analytical principles to ensure data integrity:

- Calibration: perform device calibration before each test. Radar and photometric launch monitors may drift between sessions.

- Validation: validate that measurements reflect true physical changes (e.g., verify carry change corresponds to expected launch/spin adjustments).

- Uncertainty estimation: compute standard deviation and 95% confidence intervals for primary metrics (ball speed, spin, launch angle).

- Outlier handling: define rules for discarding shots (mis-hits based on impact tape or ball speed deviation).

data analysis: turning numbers into actionable insights

Useful analytical approaches include:

- Descriptive statistics: mean, median, standard deviation for each metric and club configuration.

- Comparative analysis: paired t-tests or non-parametric equivalents to compare two club setups for meaning.

- Correlation & regression: model carry distance as a function of ball speed, launch angle, and spin to find optimal launch windows.

- Principal component analysis (PCA): reduce dimensionality when tracking many metrics across multiple clubs/balls.

- Heat maps: visualize dispersion patterns (landing locations) to evaluate shot grouping and forgiveness.

Practical testing checklist (printable)

- Calibrate launch monitor & camera

- Confirm ball model & serials

- Set up club loft/lie measurement

- Warm-up completed

- Record baseline repeat shots

- Collect minimum 30 valid strikes per club/ball

- Log environmental conditions

- Export raw data (CSV) for analysis

Quick reference table: typical target ranges by club

| Club | Ball speed (mph) | Launch angle (°) | Spin rate (rpm) |

|---|---|---|---|

| Driver | 140-180 | 10-14 | 1,800-3,200 |

| 5-wood / Hybrid | 115-140 | 12-18 | 2,500-4,000 |

| 7-iron | 90-115 | 15-20 | 5,000-7,500 |

case study: fitting a mid-handicap player for a driver

Scenario: A 12-handicap amateur seeks a new driver to increase carry without sacrificing accuracy.

- baseline data: clubhead speed 95 mph, ball speed 137 mph, launch 9°, spin 3,400 rpm, carry 230 yd.

- Goals: increase carry to 245 yd with a tighter dispersion.

- Protocol: test three drivers (9°, 10.5°, adjustable head) with three shaft flexes (stiff, regular, senior). 40 valid strikes per configuration. Launch monitor+high-speed capture used.

- Findings: The 10.5° head with a mid-kick regular shaft raised launch to 12.2°, reduced spin to 2,800 rpm, increased ball speed slightly to 139 mph, and achieved average carry 246 yd. Dispersion decreased (SD of carry from 18 yd to 11 yd).

- Actionable outcome: select the 10.5° driver with the identified shaft; adjust driver loft by +0.5° in the clubhead if needed for course conditions.

Evaluating new materials & design innovations

Modern driver faces, carbon crowns, and advanced shaft composites affect performance in measurable ways:

- Face metallurgy: different alloys and face thickness patterns change COR and ball speed; quantify via ball speed and smash factor tests.

- Carbon crown and weight placement: repositioning mass affects MOI and launch/spin; measure via MOI rig and on-course dispersion analysis.

- Shaft material and torque: change feel, timing, and effective loft at impact; evaluate with high-speed video and shaft load/torque testing.

Putting analytics to work: fitting, testing, and buying decisions

How to use test results to make real decisions:

- Fit to the player, not the spec sheet: choose the configuration that gives the best combination of carry, dispersion, and landing angle for the player’s swing speed and typical course conditions.

- Prioritize repeatability: a club that delivers slightly less peak distance but much tighter dispersion is ofen better for scoring.

- Consider ROI: balance cost vs. measurable performance gain.Expensive innovations should show statistically significant improvements to justify purchase.

Practical tips for coaches, fitters, and DIY testers

- Use the same ball model across tests-ball construction affects spin and launch markedly.

- Keep the player’s routine consistent; psychological factors change outcomes.

- Export raw CSV/JSON from devices for deeper analysis in software (Excel, R, Python).

- Create a testing logbook (club serial,settings,date,indoor/outdoor) to track performance over time.

- When in doubt, run a blind A/B test: player or fitter doesn’t know which club is being used to reduce bias.

Common pitfalls and how to avoid them

- ignoring environmental effects: temperature and altitude change ball flight-control or log them.

- Small sample sizes: don’t trust 5-10 swings; aim for 30+ valid shots per configuration.

- Mismatched equipment: comparing different ball models or using uncalibrated devices yields false positives.

- Overfitting to numbers: don’t chase single metrics (e.g., max ball speed) at the expense of playability.

SEO & content tips for publishing equipment test results

- Use keywords naturally: “golf equipment performance,” “launch monitor,” ”club fitting,” “spin rate,” “carry distance.”

- Include data tables and downloadable CSVs to increase user engagement and time on page.

- Provide clear H1/H2/H3 structure and descriptive alt text for images (e.g., “launch monitor shot scatter plot”).

- Link to authoritative sources on testing methodology (manufacturers and analytical method references, such as ACS Analytical Chemistry lifecycle guidance).

Frequently asked questions (FAQ)

How many shots are enough for a valid comparison?

A minimum of 30 valid, repeatable strikes per configuration is a good starting point. For higher confidence, 50-100 hits reduce uncertainty and better reveal small differences.

Should I trust phone-based launch apps?

Phone apps and low-cost devices can be useful for trends but lack the absolute accuracy and calibration of professional launch monitors. Use them for preview testing but verify findings on a calibrated system for purchase decisions.

how do I know a change is statistically significant?

Use paired statistical tests (paired t-test if normally distributed) comparing means and consider the practical significance-e.g., a 2-3 yard average increase might potentially be statistically significant but not meaningful for play.

If you want, I can generate a printable test-plan template or a CSV export-ready data sheet you can use in your next club fitting or gear evaluation session.