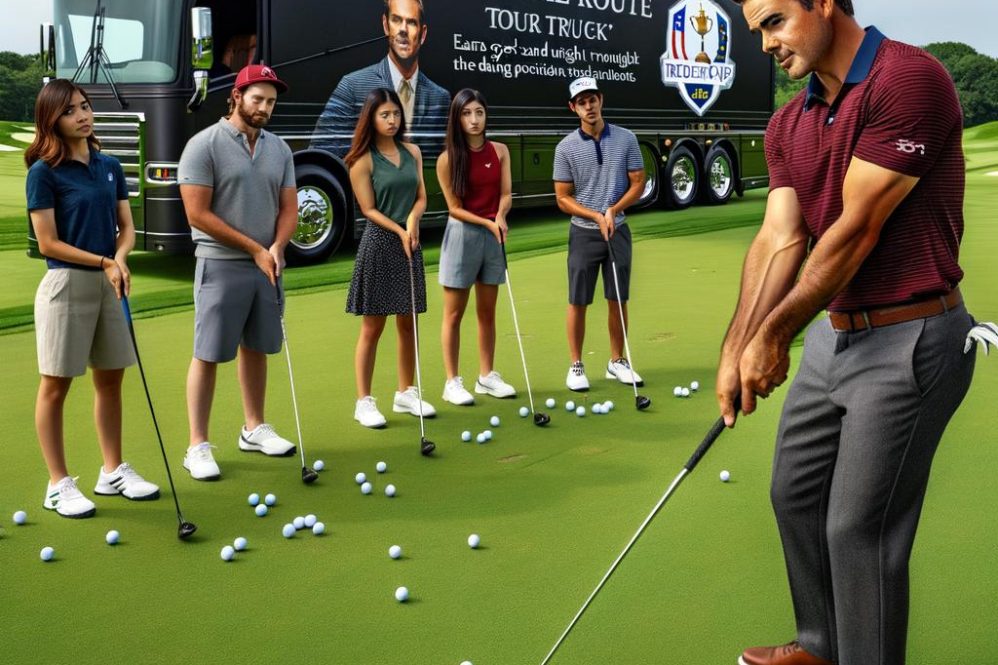

At Bethpage Black for the Sept. 26-28 Ryder Cup, a dedicated tour truck is operating as a centralized support hub – a mobile service center supplying clubs, bespoke fittings, emergency repairs, apparel and consumables to simplify logistics for players, caddies and support teams across the three-day event, wich gets underway each morning at 7 a.m. ET.

New Open qualification route gives LIV players direct access via set events and performance benchmarks, altering major-entry dynamics and sparking discussion

Recent seasons have introduced broader avenues into golf’s biggest tournaments, raising competitive standards and requiring newcomers to sharpen core skills to handle major-championship conditions. No matter your level,reliable fundamentals are the foundation: a shoulder-width stance for mid-irons,the ball just inside the front heel for drivers (about one club length forward),and a consistent spine angle near 20° at address. Pay attention to local rules and course state: links-style venues or sodden fairways common at The Open demand different strategies, including use of R&A/USGA guidance on abnormal course conditions and any permitted preferred-lie policies. Moving from a standard tour set-up into firm, windy links conditions requires repeatable fundamentals to limit variability when the pressure is highest.

Instruction should be outcome-driven, with clear checkpoints to measure improvement. Start with a structured backswing-to-impact blueprint: (1) aim for a centered weight transfer – roughly 60:40 weight distribution from backswing to finish for most amateur players; (2) maintain a wrist hinge near 30° at the top to preserve lag; (3) target a slightly positive driver attack angle, usually +2° to +4°, and negative attack for long irons around -2° to -5°. Use focused drills to ingrain these motions:

- Three-quarter pause drill – halt at ¾ of the backswing,then complete the motion to reinforce sequencing (20 reps).

- Impact-bag reps – short swings into an impact bag to feel forward shaft lean and a square face (10 reps per set).

- Launch monitor audits – capture carry, spin and smash factor to track progress (for example, aim to reduce long-iron spin by 200-500 rpm).

The short game delivers outsized returns for the hours invested. For chips and pitches, make clean contact the priority: place the ball slightly back of center for lower, running chips and move it forward for higher flop shots; maintain wrist stability and a compact arc for accuracy. From bunkers,adapt technique to the lie – use an open face with a steeper entry for plugged lies,and a more neutral face with contact 1-2 inches behind the ball in soft sand to splash it out. A practical weekly regimen might include 50 chips from 20 yards, 30 bunker shots across different lies, and putting ladders at 6, 10 and 20 feet to build feel. Typical faults – decelerating through impact or excessive hand action – are corrected with single-plane stroke practice and drills that lower wrist hinge at the bottom of the arc.

Smart course management separates good rounds from great ones. Players entering majors through new qualification routes should adopt tour-like planning: use yardage sheets and wind checks (a working rule: a 10 mph crosswind can shift mid-iron shots roughly 5-10 yards laterally) and pick clubs that leave the largest margin for error around hazards. Equipment choices play a role; emulate the Tour Truck approach by testing shafts, lofts and ball models in tournament-like settings before competition.Actionable steps: schedule a launch-monitor fitting, trial loft/lie tweaks to observe trajectory and dispersion changes, and identify a set of conservative “go-to” targets on the course to reduce risk and improve scoring consistency at championship level.

Physical and mental conditioning completes the improvement loop with measurable objectives and corrective plans. Set short-term targets – for example,halve three-putts within four weeks or raise fairway-hit percentage by 10 percentage points. Tailor goals by handicap: beginners should nail a 3-step pre-shot routine and basic balance work; mid-handicappers concentrate on distance control and short-game percentage play; low-handicap players refine trajectory control and specialty shots such as punches and crosswind knockdowns. Diagnosis tools – video analysis for early extension, mirror holds for posture, and tempo metronomes – help isolate issues, while simulated-pressure drills (match play, small-stake scenarios) tie practice to competitive decision-making so gains appear on the scorecard.

How the Tour Truck acts as an on-course clubhouse for repairs, fittings and recovery

Designed for traveling tournaments, the mobile unit operates like a compact clubhouse: repair bay, fitting station and recovery area all fed by data. Observers at the Ryder Cup called it a true one-stop operation - and the coaching implication is straightforward: when equipment and recovery are dialed in, small tweaks yield measurable gains. Start by building a data baseline on a launch monitor: log each club’s carry distance, launch angle and spin rate (rpm), plus dispersion trends. Adjust fittings incrementally – loft by ±1-2°,lie in 1° steps,and shaft weight/flex in 10-20 g increments – to observe clear changes in ball flight that translate into better accuracy and scoring.

The short game is where marginal gains count most. Coaching from the truck reinforces repeatable setup: a slightly open stance for high-lofted wedges, hands positioned 1-2 inches ahead at address for crisp contact, and a modest forward shaft lean at impact (~2-4°) to manage spin. On-site drills used by touring coaches include:

- Clock-face wedge calibration (25/50/75/100% swing lengths) to map precise yardages

- Bump-and-run ladder for 20-50 yards to fine-tune release and landing zones

- Sand-swing groove: use a sand wedge with 8-12° bounce to avoid digging

These exercises target frequent faults (early extension, deceleration, wrist flip) and provide clear cues like “rotate through impact” and “accelerate the clubhead,” which produce measurable improvements in GIR and scrambling.

From ther, integrated course-management coaching delivered from the truck focuses on shaping shots and making tactical choices under pressure. Shot shape is a function of face-to-path relationship: a controlled fade typically results from a face 2-4° open to the path with a slight outside-in arc; a draw from a face 2-4° closed to an inside-out path. Players are trained to align precisely and choose conservative yardages – for instance, selecting a 3-wood to center-left of a guarded green instead of a driver to a tight fairway when crosswinds top 15 mph. The staff runs live-course simulations from the truck to teach hole-by-hole tactics so players of all levels prioritize high-percentage plays that limit penalty strokes.

Recovery and routines underpin the body’s ability to deliver under fatigue. On-site physios provide targeted pre/post-round protocols: dynamic warm-ups for thoracic rotation and hip mobility, soft-tissue work for forearms/shoulders, and brief cryotherapy or compression to speed recovery between rounds. Recommended practice blends a daily focused 30-minute block (tempo work,short game,putting) with a weekly intentional range session. mental skills training – a sub-10 second pre-shot routine, breathing techniques to manage heart rate, and imagery of preferred ball flight – is woven into plans that scale from beginners to low handicappers, ensuring the training load fits the player’s physical and learning profile.

The truck also functions as a compliance and troubleshooting hub: technicians perform re-grips and loft-and-lie tweaks while documenting changes to remain within USGA/R&A rules – for example, alterations that materially change club performance can have Rule 4 implications during competition. Coaches pair any mechanical change with follow-up reps to integrate feel into the swing. Targets are set collaboratively (e.g., increase fairways hit to 60%+, raise GIR by 10% in eight weeks, or cut three-putts by 30%) so progress is measurable. In short, the mobile hub links biomechanics, precise equipment tuning and recovery science with tactical coaching to generate stepwise score improvements.

Coordinating mechanics, fitters and medical staff to enable rapid service

At elite events where time is scarce, the truck crew – mechanics, fitters and medical professionals – functions like a motorsport pit team to ensure fast turnarounds and keep players on the course. Within this model, the initial rapid-check includes digital loft/lie readings from a mechanic, swing- and ball-speed capture from a fitter’s launch monitor, and a rapid mobility/pain screen from medical staff. The team then confirms tolerance targets – such as loft within ±0.5°, lie within ±1°, and appropriate shaft flex for swing speed (e.g., 85-95 mph = regular-stiff) – and sequences priority fixes so an adjustment, a regrip, or a light treatment can happen inside a single practice window. This evidence-based workflow preserves rhythm for coaches working on swing mechanics and strategy.

swing refinement is a collaborative effort: fitters and medical staff help ensure mechanical changes are both effective and sustainable. Coaches emphasize measurable elements – attack angle (driver ≈ −2° to +3° for irons), spine tilt (5-10° from vertical at address) and shoulder turn (80-100° for full swings). For novices, the progression focuses on setup and tempo (neutral grip, ball position one ball forward for mid-irons, and a 2:1 backswing-to-downswing ratio).Advanced players receive nuanced adjustments to face-path and release, often analyzed via high-frame-rate video (>240 fps). Typical practice tools include:

- Gate drill – alignment sticks to promote an inside-out path

- Mirror slow-motion – rehearse hip rotation to ~45° without spine collapse

- Impact-bag work - encourage forward shaft lean (target 1-2 inches on short irons)

Short game and putting are addressed concurrently as small gains there produce large scoring dividends. Fitters check wedge loft and bounce (e.g., a 50° lob wedge with 10° bounce for soft turf versus ~6° for firm) while medical staff confirm wrist and hip mobility to support consistent chipping and bunker motion. Coaches stress a repeatable setup: narrow stance, hands ahead, and slight weight forward. For putting, a simple metric such as a 2:1 stroke ratio (12-inch backstroke → 6-inch follow-through for a 10-foot putt) helps quantify feel. Useful drills include the clock drill at 3-9 feet, lag-putt targets into a 6-foot circle from 40-60 yards, and bump-and-run work across varied surfaces.

Errors commonly seen – too much wrist on chips,inactive lower body in bunkers,or inconsistent setup causing skulled shots – are corrected with explicit,measurable prescriptions (e.g., “increase hip turn by 10°” or “limit wrist hinge to ~20°”) so players can track progress.

Course management connects technical work to scoring outcomes. Tour Truck case studies show teams stage multiple club options and pre-position loft/lie adjustments for quick swaps, influencing on-course choices: when wind is 15-25 mph and a low ball is needed, play 2-3 clubs longer with a 3-5° deloft to keep the ball beneath the breeze. Match-play targets might include 60-70% fairways for mid-handicappers, or approach proximity within 25 feet for low-handicap players. Reinforcement drills include simulated-tee strategies (aggressive/neutral/conservative),wind-trajectory sequences (150/165/180-yard carry windows) and pressure putt finishes to simulate match conditions.

The workflow concludes with a compact pre-round checklist inspired by the truck model: medical screen, launch-monitor baseline, quick club audit and a 10-15 minute focused drill block on the day’s top two priorities. Troubleshooting examples:

- If shots are consistently left with a square face at impact,inspect lie and grip pressure; consider a 1° upright lie change or reduce grip tension by 20-30%.

- If knee pain limits rotation, limit hip-turn drills to 45° and coordinate rehab work with medical staff.

- If distance control slips, re-evaluate shaft flex and monitor carry numbers; target a 10-yard reduction in dispersion across four sessions.

Integrate mental cues – breathing, imagery and a concise club-selection decision tree – so technical adjustments become confident, repeatable plays under tournament pressure.

How captains should schedule and prioritize truck services during practice and match play

Set a routine cadence for truck stops that aligns with the team’s warm-up and match-day flow so players can plan fittings, repairs and short drills without derailing their rhythm. A good template: one pre-round stop at the range 60-90 minutes before tee time for fit checks and grip inspections,then a final 30-minute pre-match visit for ball and club confirmation. During these windows, capture baseline metrics – carry yards with a 7-iron, 9-iron and sand wedge – so subsequent tweaks are driven by data. The Tour Truck model at the Ryder Cup illustrates how centralized timing accelerates service delivery; map truck availability to player arrival patterns to reduce bottlenecks.

Prioritize equipment work that influences scoring and communicate clear expectations to players and staff. Verify wedge gapping of 8-10 yards between clubs, record any loft/lie changes, and reserve ~20 minutes per player for fitting if an adjustment is suspected. Keep the Rules of Golf in mind: a damaged club may be replaced if the damage didn’t result from abuse, but the 14-club limit must be observed – so stock legal spares. Key checkpoints include:

- Grip condition and sizing (replace if slick or compresses >2 mm)

- Loft/lie tolerance audits and a written change log

- Shaft integrity checks, especially for cold-weather play

These checks directly affect launch and spin profiles and can frequently enough be diagnosed during a brief 10-shot on-course swing check.

Blend practice-round truck visits with on-course instruction to fine-tune shot shape and short-game strategy. Use a mid-practice stop to review yardage books, analyze dispersion and select club/trajectory choices by pin position and wind. Immediate drills after a service stop might include:

- Wedge-distance ladder: six shots from 30-120 yards to confirm gaps until variance is ±5 yards

- Trajectory control: 7-iron knockdowns at ¾ swing on downwind holes to lower peak height by ~10-15%

- Short-game ladder: 10 attempts each from 20,30 and 40 yards aiming for 3-foot run-out variance

These exercises quickly link equipment changes to tangible ball-flight outcomes.

For match play, build fast-response protocols and clear timing so equipment support doesn’t interrupt momentum. Place the truck conveniently (clubhouse and halfway point) for swift swaps; reserve a 10-15 minute emergency window for repairs or footwear/glove changes. Brief captains and caddies on legality and process: confirm the active club set, log mid-day swaps and maintain an adjustments record.Hold brief course-management huddles at the truck to align tee locations, preferred lines and wind strategy so pairs leave with a unified game plan and fewer split-second errors.

After any truck service, require a short reintegration session (5-10 minutes) with specific goals – for example, putting-face alignment within 1-2° of target or a fairway wood carry within ±5 yards. Provide tiered drills by skill level:

- Beginners: alignment and balance cues with visual targets

- Intermediates: swing-plane work using a 45° alignment rod and metronome at 60-70 bpm

- Low handicappers: targeted trajectory/spin control confirmed with a launch monitor

Also plan contingencies for weather or tight schedules: rotate truck assignments, prioritize services and keep a compact inventory of essentials. Linking truck scheduling to measurable practice outcomes lets captains turn logistics into concrete improvements in accuracy and scoring.

What’s inside the truck: launch monitors, spare clubs and tech that deliver instant insights

Modern coaching treats launch monitors, spare clubs and tour-grade tech as baseline tools rather than luxuries. A launch monitor supplies repeatable metrics – ball speed, launch angle, spin rate, smash factor, attack angle and carry/total distance - that form objective baselines. Establish a warm-up routine: 10 calibrated swings per club from a consistent height, capture averages and standard deviations, then compare against target ranges (e.g., driver smash factor ~1.45-1.50; driver launch commonly 10°-14°; iron attack angles typically -2° to -6°). Use that data to set goals – for example, tightening 7-iron carry dispersion to ±10 yards across four weeks – and record progress after each session. The ryder cup Tour Truck proves this workflow works under tournament conditions, enabling immediate, course-specific tuning.

Armed with baselines, coaches convert numbers into targeted swing fixes. If a monitor shows face-to-path >+2° (open) causing a slice, the corrective sequence is clear: 1) square the face at setup, 2) practice a neutral release on an impact bag, and 3) groove an inside-to-square-to-out path with a gate drill. A closed face (face-to-path <−2°) producing hooks is typically addressed with a slightly weaker grip and a more neutral hip rotation. Common drills include:

- Gate drill with short irons to train path and centering

- Impact-bag progressions to reinforce square-face compression

- Tee drill for driver to promote a positive attack angle (+1° to +4°)

Set measurable aims – shrink face-to-path error by ~1° weekly and monitor dispersion improvements.

The short game benefits hugely from immediate spin and carry feedback. Use the monitor to refine wedge landings and spin windows – for instance, a full 56° wedge on dry turf often produces spin in the 6,000-10,000 rpm band; if variability is high, correct loft/strike with a forward press and lower hands at impact. Useful drills include clock drills from 5-25 yards, partial-wedge ladders (50/75/100%) and variable-lie practice to simulate turf interaction. Spare-club racks let players test loft and bounce on the spot and build a gapping chart based on verified carry differentials rather than guesswork.

Technology also sharpens course management in real time. Replace estimates with monitor-derived carry and dispersion numbers to create a personalized yardage book: log carry/total distance and variance for each club across surfaces and conditions, then use those figures when wind, slope or firmness demands precise judgment. For example, if your 7-iron shows an average carry of 150 yards ±10, you can make more confident choices on exposed or elevated greens. At match events, teams use the truck to simulate wind and firmness and practice specific shapes (low punch, high draw) so players are prepared for the course’s exact challenges. Small changes in face or path (1-2°) can drastically alter curvature - practice those tweaks with immediate monitor feedback so on-course decisions are repeatable.

Adopt a weekly, tech-informed plan blending ball-striking, short game and simulated holes with quantifiable checkpoints. Sample progression: two tech sessions (30-45 minutes) per week focused on launch data, two short-game sessions for landing/roll control, and three on-course simulation holes using verified gapping. Troubleshooting:

- If dispersion deteriorates: check grip pressure and tempo; reduce swing speed 5-10% and re-assess

- If spin fluctuates: check strike location and loft at impact; use alignment and impact drills

- If a club breaks: follow Rules of Golf for replacement and stay within the 14-club limit

Offer learning pathways for visual (video + data), kinesthetic (impact-feel drills) and verbal (concise cues) learners. Combining launch monitors, spare clubs and structured practice – the same process used inside pro Tour Trucks – helps golfers from beginners to low handicaps make measurable, repeatable improvements and turn instruction into lower scores on course.

Using the truck as a fan-facing demo and retail hub to increase engagement and income

Event teams can transform a mobile demo/retail unit into a high-value experiential hub by pairing concise, data-led coaching with on-site services. At the Ryder Cup, the Tour Truck model showed how visitors and competitors respond when lessons, fittings and merchandise coexist. Start by using a portable launch monitor to give attendees immediate metrics - ball speed, launch angle, spin rate and smash factor. Have each participant hit three controlled swings with the same ball and compare dispersion to baseline numbers; typical fitting objectives include improving smash factor by 0.02-0.05 and tightening lateral dispersion to ±10 yards.

Design the mobile space around short-game stations that scale from novice to advanced. Provide a putting mat and chipping turf so coaches can cover fundamentals: for putting, teach a 3-step routine (eyes over the ball, square blade, smooth 1:2 tempo) and set a measurable target (e.g., 80% make rate from 6 feet in 20 minutes). For chips/pitches, emphasize 60/40 forward weight and a backswing wrist hinge around 15-25° for controlled trajectories. Practical activities:

- Landing-spot practice: land into a 6-foot zone and vary loft/open face for rollout

- Lag-putt corridor: from 40-60 feet aim to finish inside 3 feet, repeat 20 times

- Three-club chipping: use one ball and three different clubs to feel roll differences

These micro-lessons give participants immediate, actionable takeaways.

Integrate full-swing diagnostics in the demo area so visitors can test adjustments on course. Coaches should analyze swing plane, face angle at impact and attack angle using slow-motion footage and launch data. Start with setup checkpoints – neutral grip, driver ball position near the inside left heel, 7-iron centered, shoulder-width stance, and a forward spine tilt of ~20-25°. Teach face-to-path changes incrementally: close the face ~3-6° versus path for a draw, open it ~3-6° for a fade, then practice small path shifts (±2-4°) with alignment rods before full-speed swings. Provide a short checklist for common fixes so visitors leave with a clear action plan (e.g., if slices persist, check face at impact and promote a stronger lead wrist and slightly inside takeaway).

The truck also functions as a tactical micro-command center: sell yardage books, hold strategy briefings and supply local-condition intel. Walk clients through hole-by-hole club selection with wind, slope and lie in mind – a practical rule: change one club per 10 mph of direct wind and subtract 0.5-1 club for firmer greens to account for extra run. teach percentage golf: aim for the green’s largest surface area, avoid hidden slopes and leave recoverable angles that favor a pitch over a blocked chip. In live scenarios, have players choose a conservative target and execute it under a time limit to link decision-making with execution.

Give visitors a clear post-visit plan: a 15-minute swing tune-up targeting one metric (e.g., cut side spin by 20%), a 30-minute club fitting to confirm loft/shaft choices that comply with USGA/R&A, or a 45-minute short-game clinic with daily drills. Offer multiple teaching modes – video, hands-on adjustments and data readouts - and recommend practice cadence (e.g., 3× weekly for 20-30 minutes) to achieve measurable gains in 4-6 weeks (targets such as a 10% GIR increase or halving three-putts). Crucially, integrate mental cues (pre-shot routine, breathing, target focus) into each session so technical gains transfer to match play.

Logistics and sustainability: tips for smooth deliveries, waste reduction and customs planning

Event teams and coaches increasingly treat logistics and sustainability as part of player preparation rather than back-of-house chores. Case studies – including the Ryder Cup Tour Truck – illustrate how centralized staging, rapid resupply and pre-cleared stock let instructors concentrate on swing work instead of sourcing gear. Adopt simple lead-time rules for international shipments (minimum 14 days for customs clearance) and allow an internal 24-48 hour buffer for last-mile delivery. These windows reduce interruptions and help maintain consistent practice conditions essential for teaching repeatable mechanics like a 5° forward shaft lean on iron strikes or a shoulder-width stance for mid-irons.

Practice-facility upkeep affects instructional quality: turf health, ball supply and waste handling determine which drills are feasible. Coordinate with grounds crews to schedule sessions when greens and ranges reflect target conditions – for example, short-game work on freshly cut 4-5 mm greens for dependable speed control. use this pre-session checklist to standardize setup and cut waste:

- Ball inventory: buckets of 30-50 reusable balls per group to reduce scatter and retrieval time

- Range mat rotation: swap mats to limit wear and recycle synthetic fill when possible

- Distance markers: flags at 25, 50, 100, 150 yards to streamline distance drills

These measures help preserve turf, reduce redundant shipments and make practice time more productive.

Swing gains come from deliberate repetition under realistic course constraints. To teach controlled fades and draws, have players use a gate drill with alignment sticks creating the desired arc: beginners begin with half swings, while low handicappers progress to full shots with a goal of landing within 15 yards of the intended line at 150 yards. core setup checks include:

- Grip pressure: maintain ~4-5/10 tension to allow natural wrist hinge

- Ball position: driver = inside left heel; mid-iron = centre; short-game = slightly back of center

- Hip rotation: aim for about 45° of shoulder turn on the backswing for controlled iron shots

Address common errors like over-rotation or early extension with a pause-at-top step drill (hold 2 seconds) to rehearse lower-body sequencing and preserve spine angle.

Short-game sessions should mirror course maintenance realities: simulate slower greens with towels or faster surfaces by lightly brushing practice cup areas (always with course permission). For pitch shots, set an objective of landing in a 12-15 yard window and judge rollout to the hole. A reliable routine:

- Choose a landing zone and take ~3 practice swings before the shot

- Organize chipping into 20 shots per distance band (0-10,10-20,20-30 yards)

- For bunker play,open the face ~15-30°,hit sand ~1-2 inches behind the ball and repeat until achieving desired trajectory in ~8/10 reps

Combining these drills with green-reading practice that accounts for grain,slope and wind leads directly to higher up-and-down rates and lower scores.

logistical preparedness and sustainability free players to focus. Teach golfers to adapt club selection to on-site conditions: when irrigation or heavy rain slows greens, expect >10% less rollout and pick a more aggressive landing spot; in stiff crosswinds, lower trajectory by moving the ball one ball-width back and shortening the swing. Support multiple learning modes with visual,kinesthetic and verbal cues and set measurable targets – e.g., improve fairway-hit percentage by 10% or drop average putts per hole by 0.3 over a month – while using centralized resources like the tour Truck to keep equipment flexible and reduce shipping waste. Together, streamlined logistics, robust waste-management practices and customs-ready planning create a stable platform for focused coaching that produces measurable technical and strategic gains at every level.

Q&A

Q: What is the “Tour truck” being described in Tour Report’s story?

A: The Tour Truck is a mobile, full-service event vehicle that serves as a one-stop operations and retail hub for players, caddies, team support and fans during the Ryder Cup. Parked close to Bethpage Black’s footprint,it houses a pop-up pro shop,fitting/demo area,club-repair bay and a fulfillment point for Ryder Cup merchandise.

Q: Why does a major team event like the Ryder Cup need a Tour Truck?

A: The intensity of a three-day Ryder Cup compresses demand for equipment, repairs and retail. The Tour Truck centralizes these services so teams can get re-grips, loft-and-lie tweaks or demo clubs rapidly without leaving the venue. For spectators, it offers streamlined access to official Ryder cup apparel and exclusive items that often sell out quickly.

Q: Who operates the Tour Truck?

A: Staffing typically blends tour equipment technicians, OEM manufacturer reps, event retail personnel and Ryder Cup operations staff, enabling the truck to support technical player services and fan transactions alike.

Q: What services does the truck offer for players and caddies?

A: Typical services include on-site club repair (re-grips, loft-and-lie adjustments), emergency shaft swaps and club builds, demo fittings with manufacturer reps, and a secure pick-up area for pre-ordered gear. The truck also functions as a logistics node for teams and a quick source of balls, tees and small accessories.

Q: What can fans expect to find at the truck?

A: Fans will encounter official Ryder Cup merchandise – hats, polos, outerwear and limited drops – plus demo clubs to inspect and a will-call station for online orders.Most trucks accept cards and contactless payments and can ship purchases on-site or after the event.

Q: Are there items exclusive to the Ryder Cup tour Truck?

A: Yes. Organizers and brand partners often release event-only merchandise and limited runs sold mainly on-site or via short online windows with same-day pickup, drawing collectors and visitors.Q: How does the Tour Truck handle inventory and demand management?

A: The truck functions as a retail and fulfillment hub: staff monitor stock in real time, coordinate restocks with central warehouses and redirect high-demand products to other retail locations across the grounds to reduce sellouts where possible.

Q: What role do manufacturers play in the truck’s setup?

A: Manufacturers use the truck to present demo clubs,carry out fittings and offer technical support to players. Their presence enables quick, in-person adjustments and gives fans a chance to see the equipment used at the highest level.

Q: Does the Tour Truck provide food, beverage or hospitality services?

A: The truck’s main role is equipment and retail, though many setups include basic hospitality – bottled water, non-alcoholic refreshments and a staffed point for crew orders. Full catering remains the duty of larger on-site concessions and hospitality tents.

Q: How does the tour Truck fit into event security and accreditation at the Ryder Cup?

A: The truck sits within the secure event perimeter and requires proper credentials for access to player-only areas. Retail-facing sides are open to public zones, while technical bays are behind credential checks to protect operations.

Q: is the Tour Truck part of a larger trend in golf events?

A: Yes. Mobile, modular retail and operations platforms are increasingly common at major tournaments as organizers look to enhance guest experiences and streamline logistics. The truck model reduces build time, concentrates expertise and creates a visible branded touchpoint.

Q: Any practical tips for fans who want to use the tour Truck?

A: Arrive early for limited releases, bring card or contactless payment, and check the event app or signage for hours and will-call rules. If you want a demo or fitting, try to book in advance - manufacturer reps often reserve morning slots for players and priority clients.

Q: Will we see more Tour Trucks at future Ryder Cups or other big golf events?

A: Organizers and brand partners value the flexibility and service the model provides, so expect to see it continue and evolve – larger fleets, improved inventory tech and deeper event-app integration are likely as tournaments enhance fan service and operational efficiency.

As the Ryder Cup plays out at Bethpage Black (Sept. 26-28), the Tour truck operates as a steady behind-the-scenes resource – a mobile hub keeping players ready and spectators engaged. Its role highlights how logistics and hospitality have become as central to modern elite golf as shot-making; follow ongoing Ryder Cup coverage from major outlets for additional behind-the-scenes reporting.

Inside the Ryder Cup’s Ultimate Tour Truck: The Secret Weapon Behind Team Success

What is the Ryder Cup tour truck and why it matters

The tour truck is the mobile operations center and equipment hub for professional golf teams at high-stakes events like the Ryder Cup. Far more than a rolling storage unit, the truck integrates club fitting, equipment repair, performance analytics, nutrition and recovery – all designed to ensure players and caddies have everything needed to perform at their peak during match play. At events such as ryder Cup 2025 at Bethpage Black,the margin for error is tiny,and tight logistics become an advantage the moment teams unload on-site. (See Ryder Cup format and schedule for context: CBS Sports, NBC Sports, CNN.)

Core components of the ultimate tour truck

To understand how a tour truck becomes a secret weapon,break down its core functions and equipment:

1. Equipment logistics and inventory management

- Secure racks and padded storage for tournament bags, spare shafts, heads and grips.

- Inventory system (barcode or RFID) to track every club, shoe, and apparel item across practice rounds and match days.

- Emergency supplies: spare clubheads, shafts, grips, tees, and replacement balls optimized to player preferences.

2. On-site club fitting and repair station

- Portable launch monitors (radar and camera-based) for distance, spin and launch-angle checks.

- Loft/lie machines, hosel adjusters and a basic shaft-fitting bench to make rapid adjustments between rounds.

- Storage of matched shafts and heads to create duplicate clubs for critical situations.

3. Performance analytics and tech hub

- Data integration station: connects launch monitor data to player performance dashboards via tablets or laptops.

- Video review corner with slow-motion capture for swing tweaks and green-reading rehearsal.

- Connectivity: dedicated mobile hotspots and power inverters to keep devices and monitors online.

4. Sports science,recovery,and medical support

- Cold-compression gear,foam rollers,massage guns and basic physiotherapy supplies.

- hydration station with electrolyte drinks and team-specific dietary supplements.

- First-aid kit and a secure area for any immediate medical attention or taping.

5. Hospitality and player comfort

- Small lounge area for meetings, rest, and tactical briefings between matches.

- Apparel racks and quick-change area for rain gear, match uniforms and footwear tuning.

- Secure lockups for valuables,passports and travel documents when the team moves between venues.

Design and layout: how trucks are organized for efficiency

Space inside a tour truck is finite, so the layout focuses on speed and reliability. Here are common design principles:

- modular racks that slide out for access – minimizes time to retrieve a specific club during warm-up or play.

- Climate control zones to protect grips, shafts and electronics from humidity and temperature swings.

- dual-entry design: one side for equipment loading and another dedicated to the tech/clinic area to avoid cross-traffic.

- Fold-down workbenches and secure mountings to keep tools safe during transit.

How the tour truck impacts performance and team success

Operational excellence off the course breeds confidence on it. The tour truck amplifies performance through:

Faster equipment adjustments

When winds change or green speeds shift, players need fast, precise changes to loft, lie or grip. Having a full club-fitting station on the truck allows for minute adjustments that can save strokes in match play.

Data-driven decision-making

Access to launch monitors and swing video in a controlled environment enables support staff to analyze shot dispersion, recommend club selection and set up practice routines tailored to course conditions – critical at venues like Bethpage Black, where course setup affects strategy. (ryder Cup schedules and formats remind us how little room there is for error over three days; see CBS sports.)

reduced downtime and stress

Immediate access to spare clubs and medical supplies reduces downtime caused by equipment failure or minor injuries. For caddies and players, that reliability reduces friction and keeps focus on strategy and shot execution.

Case studies: real-world examples of truck-driven advantages

While specific team setups vary, tournament reports and behind-the-scenes features consistently highlight the truck’s role at major team events:

- At high-profile match-play events, teams that invest in robust mobile tech and club-fitting capabilities report faster adaptation to local course conditions.

- Teams with integrated sports-science supplies – from compression gear to hydration protocols – see fewer minor injuries and better recovery between matches.

- Logistics-savvy teams that use inventory tracking avoid costly delays when assembling identical backup clubs for players.

Practical tips for building a high-performance tour truck

Whether for a national team, a professional group, or an enterprising collegiate squad, here are practical, actionable tips:

- Prioritize modular storage: invest in sliding racks and labeled, removable bins for quick retrieval.

- Create a digital inventory: a simple spreadsheet or barcode system prevents misplacement of critical equipment.

- Include a small fitting area with a portable launch monitor and a video capture rig – this pays dividends in practice efficiency.

- Stock redundancy: keep at least one full backup set of clubs for each player and multiple shafts at common flexes and lengths.

- ensure power resilience: multiple inverters, spare batteries and portable chargers keep devices running in remote venues.

- Allocate a recovery corner: a compact area with a massage gun, cold packs and foam roller for immediate treatment.

First-hand logistics: what support staff prioritize on match day

Staff interviews and operational summaries from major golf events reveal a consistent list of priorities:

- Readiness: Ensure each player’s primary and backup sets are staged and labelled.

- Speed: Rapid access to tools for on-the-spot adjustments during warm-ups.

- Communication: Seamless data flow between launch monitor results and player coaching plans.

- Comfort: A quiet, controlled space where players can mentally rehearse and refuel between matches.

- Security: Lockable storage and chain-of-custody for high-value equipment, especially during travel between courses.

Typical inventory checklist (compact and practical)

| Zone | Typical Items | Purpose |

|---|---|---|

| Equipment | Spare clubs, grips, shafts, balls | Quick replacement and matching |

| Tech | Launch monitor, tablets, cameras | Performance analysis & club fitting |

| Recovery | Cold packs, compression, massage tools | Speed up recovery between matches |

| Hospitality | Drinks, snacks, apparel racks | Player comfort & nutrition |

SEO-driven content strategy: keywords and how the truck story ranks

To optimize content about a Ryder Cup tour truck for search engines, naturally weave in the following long- and short-tail keywords:

- ryder Cup tour truck

- golf equipment logistics

- tour truck club fitting

- performance analytics in golf

- pro golf equipment van

- caddies and team support

- Ryder Cup 2025 Bethpage black

Best SEO practices for this topic:

- Use H1 for the primary topic (as above) and H2/H3 for subsections to help search engines parse structure.

- Include internal links to related articles (logistics,club fitting,sports science) and authoritative external links when referencing the event or format (e.g., CBS Sports).

- Optimize meta title and description with target keywords to improve click-through rate on SERPs.

- Include images of the truck interior and alt text such as “Ryder Cup tour truck club fitting station” to capture image search traffic.

FAQs: quick answers to common reader questions

Q: Do both teams bring tour trucks to the Ryder Cup?

A: Yes – national and regional teams, plus their support staff, typically bring mobile equipment vans or trucks. These vehicles are essential for transporting player gear and providing on-site support during practice and match days.

Q: Can the tour truck be used as a tactical hub?

A: absolutely - the truck serves as an operations center for data review, strategy meetings and equipment decisions, helping captains and coaches make informed choices in the pressure of match play.

Q: Is investing in a tour truck worth it for smaller teams?

A: Even scaled-down versions - a well-organized trailer or van with basic fitting tools, a launch monitor and recovery supplies – can deliver a measurable performance advantage at regional and collegiate levels.

Next-level ideas: innovations shaping future tour trucks

- Integrated cloud dashboards linking shot data from practice to match-day plans in real time.

- AI-assisted club recommendation engines that analyze historical performance on similar greens and wind conditions.

- Solar-powered charging systems and lightweight modular racks to reduce travel footprint while increasing on-site endurance.

At the Ryder Cup and other elite golf competitions, the tour truck is more than logistics – it’s a competitive multiplier. By combining club tech, sports science, hospitality and smart inventory practices, teams create a mobile secret weapon that supports players and caddies through the toughest, most significant moments of match play.